Product Gallery

CHARACTERISTICS

Automatic Testing System for Microbial Nucleic Acid

High-flux “Sample In & Result Out”

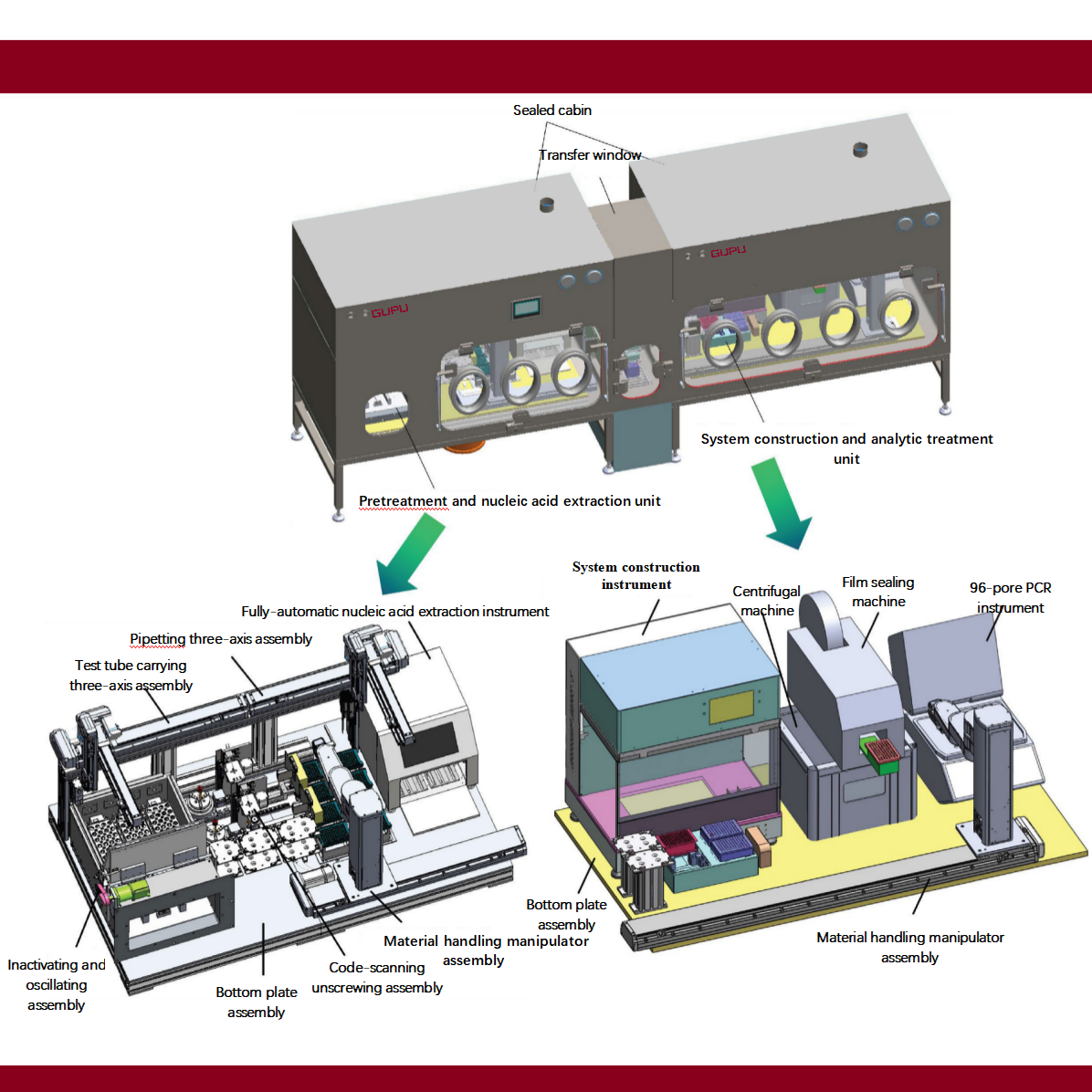

The Testing System for Microbial Nucleic Acid is divided into two sealed cabins: the 1st sealed cabin is a Virus Specimen Pretreatment and Nucleic Acid Extraction Functional Unit, and the 2nd sealed cabin is a System Construction and PCR Analysis Treatment Functional Unit.

Materials such as the reagent, the 96-pore plate, the magnetic sleeve, the TIP head, the 96-pore PCR plate and the like are manually installed on the Transfer Window Material Shelf (positioned between the two sealed cabins) and then are carried to the corresponding material storage station by the handling manipulator assembly. The virus specimen test tube enters from the entrance of the inactivated cabin on the front side of the device. The reagents, consumables and the like used in the two sealed cabins are recovered by the waste safe recovering device.

Main Performance Specification

Max Input of Single Pathogen Sample: | 96 tubes |

Pathogen Sample Inactivation Temperature and Time | 50℃~70℃Adjustable |

Parallel Extraction Flux of | ≥32 |

Testing Pores of | ≥96 |

Single-pore Fluorescence Channels | 6 |

Full System Testing Flux | ≥1200 samples/24h |

Overall Dimensions(W*D*H) | 4500×1150×2000mm |

The Reduced Workload of Medical Workers | ≥50% |

DESCRIPTION

Ø Main configuration of Pretreatment and Nucleic Acid Extraction Unit

The Pretreatment and Nucleic Acid Extraction Unit mainly comprises the material handling manipulator assembly, the inactivating and oscillating assembly, the unscrewing code-scanning assembly, the test tube carrying three-axis assembly, the pipetting three-axis assembly, the fully-automatic nucleic acid extraction instrument and the like, and completes fully-automatic operation of virus specimen test tube input, sample inactivation, oscillation and mixing, test tube code scanning and unscrewing, pipetting, nucleic acid extraction, etc.

S.N. | Configuration | Quantity | Main Function/Parameter |

1 | Material handling manipulator | 1 | (1) the number of axes: 5; (2) carrying the 96-pore deep pore plate, etc. |

2 | Inactivating and oscillating assembly | 1 | (1) flux 96; consisting of three 32-pore test tube racks, flexible to change; (2) inactivation method: heating at high temperature; (3) range of inactivation temperature: 50℃~70℃; (4) inactivation time: 30 min to 90min. |

3 | Unscrewing code-scanning assembly | 2 | (1) for opening and closing the throat swab tube |

4 | Test tube carrying three-axis assembly | 1 | (1) for transferring the throat swab tube among the test tube rack, the unscrewing station and the liquid taking station |

5 | Pipetting three-axis assembly | 1 | (1) single-channel electronic pipette; (2) pipetting range: 100-1000 microliters; (3) pipetting precision: ≤1%; and (4) it takes about 30 min to transfer 96 pieces of liquid |

6 | Fully-automatic nucleic acid extraction instrument | 1 | (1) flux: 32; (2) the pore plate is automatically pushed in and out; (3) the magnetic sleeve is automatically assembled and disassembled; (4) extraction method: magnetic bead transfer method; (5) volume of the treated sample: 20 μL to 1000 μL; (6) the heating temperature of the pore plate pedestal is 30℃ to 90℃; (7) the recovery rate of the magnetic bead: ≥95%; (8) difference between the extraction pores: CV≤3% (PCR amplification CT value); (9) embedded touch screen (including network communication), capable of working independently; (10) the single extraction time is about 30min/32 persons (the extraction time varies with different reagent requirements). |

Ø Main configuration of System Construction and Analytic Treatment Unit

The second part mainly comprises the five-axis handling manipulator, the system construction instrument, the film sealing machine, the centrifugal machine and the 96-pore PCR instrument.

Step 1 take out the 96-pore shallow pore plate, the amplification reagent, the deep pore plate (which has completed nucleic acid extraction and other materials) from the transfer window,

Step 2 put the materials into the corresponding station of the system construction instrument,

Step 3 perform PCR reaction system construction, sequentially feed the 96-pore shallow pore plate into the film sealing machine and the centrifuge to perform film sealing and centrifugal operation,

Step 4 feed into the PCR instrument to perform amplification testing, finally output the inspection report.

S.N. | Configuration | Quantity | Main Function/Parameter |

1 | System construction instrument | 1 | (1) the number of plate position: 4 (2) the platform is automatically pushed in and out; (3) in-place testing of the plate position (4) single-channel electronic pipette; (5) pipetting range: 5-200 microliters; (6) pipetting precision: ≤1% (20<V≤200μL), ≤5% (5≤V≤20μL) (7) it takes about 0.5 h to establish the 96-pore system; (8) with a liquid level testing function; (9) Windows touch screen (including network communication), capable of working independently. |

2 | Film sealing machine | 1 | (1) plate position: 1 (2) transparent film; (3) the heating temperature: 100℃ to 200℃; (4) film sealing time: 0.1 s to 10 s. |

3 | Centrifugal machine | 1 | (1) suitable for the 96-pore plate; (2) plate position: 1; (with balance weight) (3) maximum rotating speed: 5000 r/min. |

4 | 96-pore PCR instrument | 1 | (1) maximum heating and cooling rate: 5℃/s; (2) temperature control range: 0℃ to 100℃; (3) temperature accuracy: ±0.2℃ (the temperature is set as 90℃) (4) temperature uniformity: ±0.4℃ (within 10 s after reaching 90℃) (5) fluorescent channels: 6; (6) range of excitation/emission wavelength: 450-730 nm (7) dynamic range: 10 order of magnitudes; (8) sensitivity: single copy human genomic DNA target sequence |

5 | Five-axis material handling manipulator | 1 | (1) the number of axes: 5; (2) carrying the 96-pore deep pore plate, etc. |